When de-risking the development of biomethanol plants, it is imperative to recognize that early-stage decisions often carry significant implications for the project’s overall viability

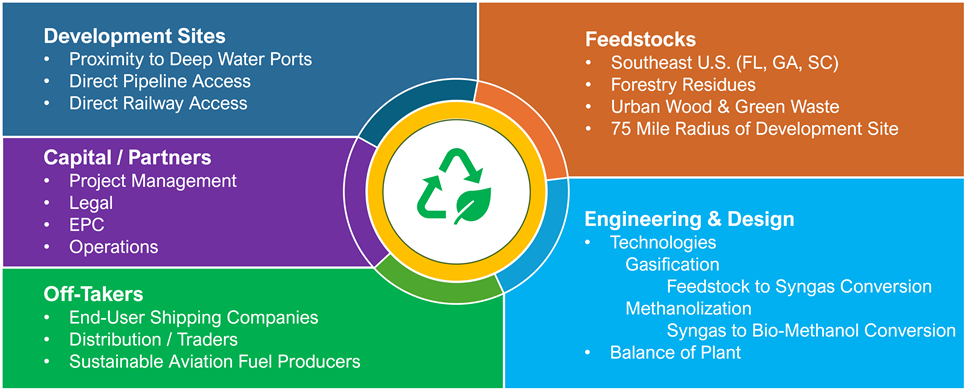

Achieving success in the development of biomethanol plants hinges on effectively addressing several critical components. These include securing sustainable feedstocks, selecting reliable technologies, identifying suitable development sites, ensuring robust financial planning, establishing strong partnerships, and navigating regulatory uncertainties. Early-stage decisions in these areas often carry significant implications for the project’s overall viability.

Demeter’s expertise in these areas positions us as a valuable development partner, particularly in the Southeastern United States, due to our extensive knowledge and access to substantial volumes of forestry feedstock.

Feedstock and Site Selection in the Southeastern U.S.

The U.S. South is one of the world’s richest and most resilient sources of wood, with over 200 million acres of forestland and a robust, year-round harvest infrastructure, making it ideal for large-scale renewable fuel operations.

At Demeter, leveraging our in-depth knowledge of the forest industry, we oversee the entire supply chain, collaborating with institutional timberland owners, local co-ops, timber dealers, brokers, and loggers. This extensive network guarantees consistent access to premium pulpwood, chips, mill residues, and harvest byproducts, enabling us to customize procurement for any project. Our strong partnerships with state agencies and regional leaders further enhance our operations, aligning us with local priorities, unlocking incentives, and streamlining the permitting process.

We prioritize supply chain integrity and compliance, designing our feedstock programs that meet rigorous traceability standards for RFS2, FuelEU, and other low-carbon fuel initiatives, ensuring every ton we source is fully verifiable, and every strategy is bankable, compliant, and grounded in strong public-private partnerships.

- Site Selection through Regional Expertise

- Real Estate Identification & Negotiation

- Tailored GIS data platform for in-depth analysis of AOI

- Real Estate and Parcel Data

- Utility, Pipeline, & Port Transport Infrastructure

- Workforce Analysis

- Tailored GIS data platform for in-depth analysis of AOI

- Logistics & Infrastructure Analysis

- Input/Offtake Optimization

- Incentive Packages

- State & Local Negotiations

- Regional Community Support

- Real Estate Identification & Negotiation

- Feedstock Procurement and Validation

- Tailored forest biomass database across multi-state zones that includes:

- Inventory & Pricing

- Competition

- Sustainability

- Procurement Strategy

- Feedstock Supplier(s)

- Processing

- LOI’s & Contracts

- Tailored forest biomass database across multi-state zones that includes:

Engineering and Design

Pre-engineered plants offer significant economic value by leveraging repeatable designs and trusted, proven models. With 80% of the plant design standardized across projects, these systems reduce both time and costs associated with custom engineering and development. This repeatability ensures reliability and efficiency while maintaining flexibility, as the remaining 20% of designs are reserved for balance of plant designs tailored to site-specific requirements. Demeter’s preconfigured plants capitalize on leading-edge technologies offering scalable solutions capable of producing between 100K to 225K metric tons of biomethanol annually. By utilizing 400K to 1M metric tons (wet) of forestry wood feedstock, these plants demonstrate not only economic efficiency but also sustainability, making them a trusted choice for scalable, cost-effective biofuel production.

Repeatable Plant Engineering and Design

- Project Description

- Site Plan

- Basic Engineering Package

- Plot Plan/General Arrangement

- Process Flow Diagram

- Block Flow Diagram

- Preliminary Heat and Mass Balance

- Project Schedule

- Utility Interconnections

- Inputs/Outputs (Water, Power, Gas, Slag/Ash)

- Development Cost Budget

- Direct Capex Estimate & Project Cost Estimate (Budgetary)

- Preliminary Emissions Estimates

- Permitting Plan

Benefits of Building Smaller Biomethanol Plants

(Less than $1 Billion CapEx and 1 Million Tons of Feedstock)

Biomethanol plants with a capital expenditure of less than $1 billion and a feedstock capacity below 1 million tons offer distinct advantages compared to larger-scale facilities. These modular and small-scale development approaches present numerous compelling benefits, effectively mitigating risks and enhancing project viability:

- Lower Investment Risks: Smaller plants require less initial capital, making them more accessible to investors and reducing the financial burden of large-scale projects.

- Lower Operating Cost: These plants can be located closer to feedstock sources and have a smaller haul radius, thereby minimizing fiber sourcing costs and supply chain complexities.

- Scalable Growth: Starting small allows for incremental expansion based on market demand, enabling smoother scaling and risk management.

- Adaptability to Market Conditions: Modular designs provide the agility to adjust to evolving market or regulatory environments without the constraints of a large-scale facility.

- Faster Implementation: With prefabricated components, modular plants can be deployed more quickly, accelerating the timeline for production and revenue generation.

Questions? We Look Forward to Hearing From You.