Demeter Energy is a project developer that specializes in de-risking biomethanol projects.

Demeter Energy focuses on de-risking the development of mid-scale biomethanol plants. Our efficient project execution strategy ensures critical elements are secured early in the lifecycle, including long-term feedstock agreements lasting around 20 years, control of development sites with direct access to transportation networks such as pipelines or railways, and rapid permitting approvals facilitated by local governments.

Success is further supported by the selection of proven technologies, standardized engineering designs, and strong financial foundations combining sufficient equity and accessible debt financing. Our repeatable processes minimize risks while maximizing speed and efficiency of plant development.

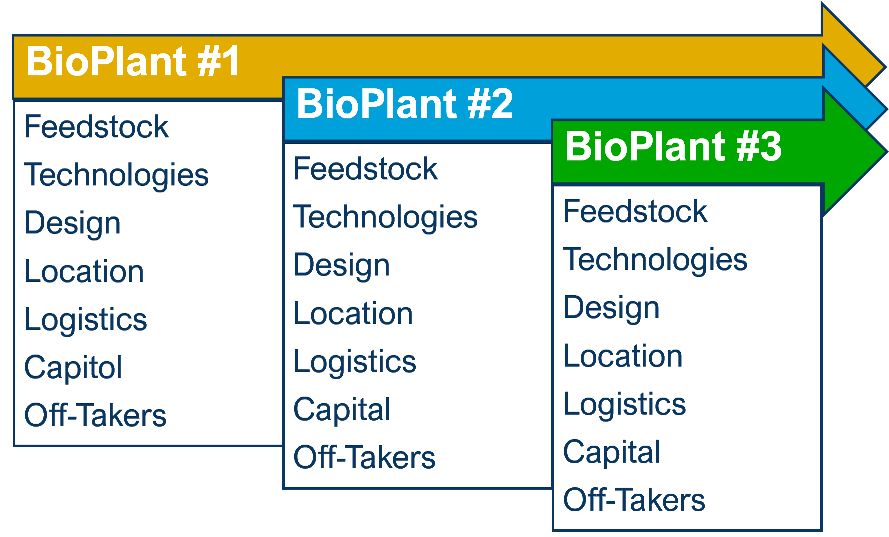

Our multiple project development strategy emphasizes a repeatable design methodology where projects are designed once but can be developed multiple times, ensuring efficiency and consistency. This approach relies on a sequential project origination process combined with stackable development cycles, which streamline operations across various initiatives.

A key element of this strategy is the use of homogenous feedstock in combination with repeatable technological designs. This standardization not only enhances operational efficiency but also ensures compatibility with repeatable off-take clients.

Furthermore, reusable financial models optimize resources, control cost, and reduce risk. By adhering to repeatable and systematic processes, this methodology effectively maximizes value, minimizing inefficiencies, and most importantly de-risks each of the projects.

Project Profiles

Scalable / Modular Design = Rapid Development / Deployment

The growing demand for biomethanol, spurred by the rapid expansion of the shipping industry’s adherence to government regulations, underscores an urgent need to develop production plants quickly and efficiently. With a projected shortfall of 3 million tons of green methanol by 2028, against a total production capacity of just 14 million tons, the pressure is mounting. Looking ahead, the staggering requirement of 540 million tons by 2050 highlights the necessity of adopting innovative and streamlined approaches to plant development. Ensuring secure swift access to long term feedstock agreements and minimizing bottlenecks in the plant development process will be pivotal to meeting this escalating demand.

- Capital Expense: $400M – $850M

- Biomethanol production:

- 100K – 250K metric tons/year

- Bi-Products:

- Vitrified Slag and Carbon Dioxide

- Feedstock: Forest Residues

- 400K – 1M metric tons/year (wet)

- Technologies:

- Feedstock to Syngas Conversion

- Syngas to Biomethanol Conversion System

- Plant Locations:

- Feedstock source: within 75 miles

- Direct pipeline or rail access for product distribution

Questions? We Look Forward to Hearing From You.